How to Maintain and Extend the Life of Your Paved Surfaces?

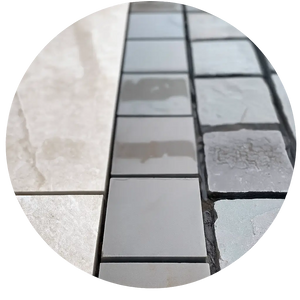

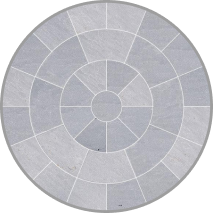

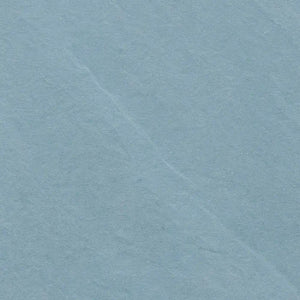

Paved surfaces are structures that provide a flat, hard surface for people and vehicles to travel on. These surfaces can be found in parking lots, driveways, walkways, streets and other areas where a durable surface is needed. Paved surfaces range from asphalt pavement to concrete roads and even the more decorative kandla grey Indian sandstone paving slabs which offer unique visual appeal as well as durability. No matter what material your paved surface is made of, proper maintenance and preservation is essential to extend its life span.

Cleaning and Maintenance

Yearly inspections are key to ensuring that your paved surface is in good condition and can withstand the wear of traffic and weather. During a yearly inspection, any cracks or potholes should be noted, along with any debris build-up or oil spills on the pavement. In addition to these physical factors, it is important to take into account the surrounding environment when assessing the condition of your paved surface. For instance, if there are trees nearby that could be dropping leaves or pine needles onto your driveway during the autumn months, this should also be taken into consideration as part of an overall maintenance plan.

The next step in proper cleaning and maintenance of a paved surface is regular power washing. This will remove dirt, dust, and other particles which may have accumulated over time due to environmental factors like wind and rain. It’s best practice to do this at least once per year either in spring or summer depending on where you live; however more frequent washings may be necessary if the area sees heavy vehicle traffic frequently throughout the year. Be sure not to use too high a pressure setting when washing as this can cause damage rather than cleanliness! Afterward, it’s important to seal coat your paved surface with asphalt sealer so that it has some protection from UV rays and water infiltration – both of which can lead to deterioration over time without treatment.

Finally for areas that experience colder temperatures often de-icing chemicals such as rock salt must be applied carefully before snowfall occurs so that ice does not build up on top of already wet surfaces (this would create dangerous driving conditions). Salt application should happen only after all other steps have been completed since they will reduce effectiveness otherwise, but make sure not too much gets used as large amounts can corrode concrete surfaces over time!

Also, Read: Common Paving Materials and Their Characteristics

Repairing and Sealing Defects

Repairing and sealing defects on a paved surface is the best way to extend its lifespan and keep it looking great for years to come. The first step in repair is to identify exactly what type of defect you are dealing with, as this will determine your approach. For example, cracks or potholes may need to be filled in with asphalt patch mix while other problems like crumbling edges or birdbaths may require more extensive repairs such as saw cutting and replacing sections of the pavement.

Once any necessary repairs have been made, sealing should be done next. This process involves applying an asphalt sealer which helps protect against UV rays and water infiltration that can lead to deterioration over time without treatment. Sealing also helps maintain a smooth driving surface by filling in small irregularities caused by everyday wear and tear from vehicles passing over it regularly; making sure there’s no loose gravel lying around either before you start is key!

Finally, once all repairs are completed and sealed up properly make sure that your paving job lasts even longer by using preventative measures like regular power washing (to remove dirt/dust), de-icing chemicals in winter months when appropriate (for areas with cold climates) and yearly inspections so that any new damage can be identified quickly before it becomes too severe! All together these steps will help keep your paved surface looking great for many years down the road – something everyone wants!

Extending Pavement Life

Replacement and Recycling Options:

Replacing an old or damaged paved surface is one way to extend its life, but it can also be costly. Alternative options such as asphalt recycling or repaving with new material are possible ways to save money while still providing the same level of durability. Asphalt recycling involves heating up existing pavement material and mixing it with new asphalt binder to create a fresh, long-lasting surface. Repaving with recycled material like rubberized asphalt can also be done which has the added benefit of being more environmentally friendly than traditional materials.

Proper Use of Deicing Materials:

Using deicing chemicals in colder climates is essential for keeping walkways and roadways safe; however, misuse can lead to significant damage over time if not used properly. Most common salts (e.g., calcium chloride) should only be applied when the snow has already begun falling so that they don’t have time to get washed away by rain or other natural elements before their job is finished; likewise, never apply salt directly onto your paved surface – instead, always use it on surrounding soil for better results!

Stabilizing Subsoil:

The subsoil beneath paving surfaces plays an important role in how well they will stand up against wear from traffic and weather conditions over time; this is why stabilizing the subsoil prior to pouring any concrete or laying down any asphalt is key for extending pavement life expectancy! Stabilization techniques involve compaction processes that help strengthen weak soils and make them less prone to shifting during freeze/thaw cycles throughout winter months – something all pavements need protection from!

Also, Read: What is Rippon Buff Sandstone and What Makes them Ideal for Paving?

Overall Preservation Strategies

Drainage Considerations:

For paved surfaces to be long-lasting, proper drainage is essential. Poor drainage can lead to water pooling on the surface and causing damage over time. It is important to identify any areas where inadequate drainage could occur and address them before they become a problem. This can include adding catch basins or drains along with grading the pavement slope in order to ensure that water flows away from the area rather than collecting on top of it.

Applying Protective Coatings:

Applying a protective coating such as seal coat or asphalt emulsion will help protect your paving against UV rays and wear due to traffic and weather conditions. The type of coating chosen should depend on what kind of surface you are dealing with; for example, if you have an asphalt driveway then you would use an asphalt sealer whereas concrete surfaces require a different product altogether like a concrete sealer. Make sure that whatever type of protective coating you choose is applied properly according to the manufacturer’s instructions so that it lasts as long as possible!

Repaving Properly:

If necessary, repaving should only be done after all other steps have been completed first in order for it to be effective; this includes draining considerations, applying protective coatings (if applicable) and making sure that the subsoil has been stabilized prior laying down any new material like concrete or asphalt mix. When repaving there are several different types of materials available depending on budget constraints – these range from traditional options such as asphalt paving all the way up through more decorative choices like cobblestone pavers which can add unique visual appeal while still providing a durable surface for vehicles or pedestrians alike! No matter what option you decide upon make sure that installation is done correctly according to manufacturer guidelines so your new paved surface stands up well against everyday wear and tear!

Also, Read: 5 Ways to Style Your Outdoor Space With Natural Sandstone Paving Slabs

Conclusion

In conclusion, proper maintenance and preservation of paved surfaces are essential for extending their lifespan and keeping them looking great. Regular inspections should be done to identify any defects in the pavement that need repair or replacement; these can include cracks, potholes, crumbling edges, birdbaths, etc. Repairs should always be followed by sealing with an asphalt sealer which will help protect it against UV rays and water infiltration – both of which can lead to deterioration over time without treatment. Furthermore, when temperatures drop deicing chemicals such as rock salt must also be applied carefully before snowfall occurs so ice does not build up on top of already wet surfaces (this would create dangerous driving conditions). Additionally stabilizing the subsoil beneath paving surfaces helps strengthen weak soils making them less prone to shifting during freeze/thaw cycles throughout winter months – something all pavements need protection from! Finally applying a protective coating like a seal coat or asphalt emulsion will help protect your paving against UV rays and wear due to traffic and weather conditions while still providing a durable surface for vehicles or pedestrians alike! All together taking care of your paved surface through proper maintenance is key if you want it to last many years into the future!